Mountain XT - Stain BaseDeck Stain | Siding Stain | Log Finish | TimbersMountain XT is the Worlds Best Exterior Wood Finish! XT is incredibly beautiful, long lasting and doesn't allow black mold stains to penetrate the film surface. Not only that, but it's sustainable. Made from bio-renewable ingredients, Mountain XT is safe and looks GREAT!!!

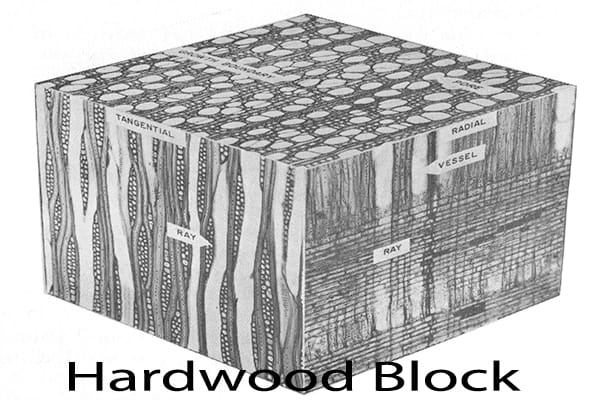

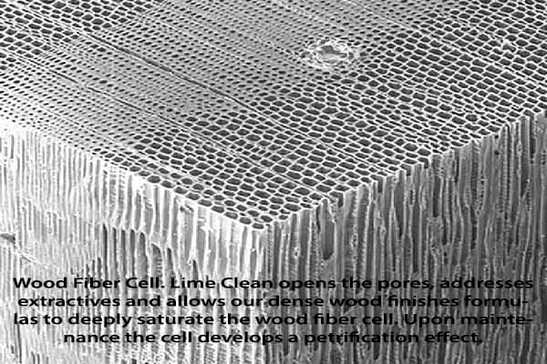

This wood finish is super tough and doesn't have any poisons common to typical deck stain and log finish. Our unique cashew resin doesn't support mold, mildew and algae growth and can be washed and maintained, safely, year after year, with relative ease. All of the ingredients work in concert to fully saturate the wood fiber cell. This high density, cellular saturation is the principle behind all our wood finishes. We seek to fully saturate the wood fiber cell because it looks better and lasts longer. It also creates a petrification effect upon maintenance. We achieve this because the cell becomes hardened and fortified, infused with a combination of inorganic minerals, elements, plant based solvents and super dense oils. This all adds up the the richest exterior wood finish formula on Earth! Application is easy and makes staining an enjoyable experience. Simply brush and roll into the deck, siding, timbers or logs. |

Mountain XT Uses A Super Tough Cashew Resin That Is Naturally Resistant To Black Mold Stains!

Pressure Treated Decks

|

1. Lime Clean

2. Mountain XT - Stain Base The best way to stain a pressure treated deck is to wash with Lime Clean and stain it with Mountain XT - Stain Base or Rainforest Sealer. What's not in it? NO BENZENE! Made from Cashews! NOT toxic NMP like water based polyurethane, NOT Mineral Spirits or poisonous petrochemical based solvents. There are no isocyanates used in the manufacturing process. These dangerous chemicals can infiltrate the communities near them. No IPBC. Brutal biocides and mildewcides like Butyl Carbamate, Copper-8-Quinolinolate and Benzene are absolutely unnecessary. |

New Pressure Treated Decks:

Pressure Treated wood needs to be saturated deeply. This is hard to do on new pressure treated wood and can result in a warped, split deck with splinters. Once saturation is properly done the wood will stop moving and twisting as much. Since this wood is treated with chemicals under high pressure, the wood fiber cell is initially very wet. When it dries it will tend to dry too quickly. Most moisture exiting disproportionately fast out of the ends of the boards. The sunny side will then want to cup as the under side stays wet and the end and top dry out fast. This can result in a deck board that looks like a C with bow in it.

For these reasons we don't wait for the wood to dry out for a year before we coat new pressure treated wood. The best thing to do with new pressure treated wood is wash it with Lime Clean and coat all 6 sides with a diluted coat of Rainforest Sealer or Mountain XT. We suggest coating all six sides of the board if possible, but if the deck is built already then coating as much as possible will help. Coating the board ends will help resist bowing. Coating the underside will help resist cupping. If only the top can be coated then it is best done with a diluted coat and brushed into the cracks. These extra steps can pay off greatly in the long term, making the long term maintenance easier as well as improving the overall beauty of the deck.

Pressure Treated wood needs to be saturated deeply. This is hard to do on new pressure treated wood and can result in a warped, split deck with splinters. Once saturation is properly done the wood will stop moving and twisting as much. Since this wood is treated with chemicals under high pressure, the wood fiber cell is initially very wet. When it dries it will tend to dry too quickly. Most moisture exiting disproportionately fast out of the ends of the boards. The sunny side will then want to cup as the under side stays wet and the end and top dry out fast. This can result in a deck board that looks like a C with bow in it.

For these reasons we don't wait for the wood to dry out for a year before we coat new pressure treated wood. The best thing to do with new pressure treated wood is wash it with Lime Clean and coat all 6 sides with a diluted coat of Rainforest Sealer or Mountain XT. We suggest coating all six sides of the board if possible, but if the deck is built already then coating as much as possible will help. Coating the board ends will help resist bowing. Coating the underside will help resist cupping. If only the top can be coated then it is best done with a diluted coat and brushed into the cracks. These extra steps can pay off greatly in the long term, making the long term maintenance easier as well as improving the overall beauty of the deck.

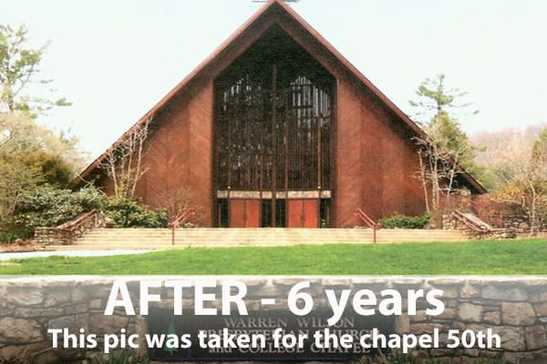

The Chapel

Sustainable Wood Finish

Mountain XT is the worlds first renewable and natural, Exterior Grade Urethane! No Isocyanates are used in its manufacture. Our Cashew Resin resists UV Radiation as well as stains like Mildew, Fungi, Algae, Water and Chemical stains. This sustainable wood finish gets exceptional coverage per gallon requiring less product to complete the job. Mountain XT isn't just a petrochemical oil that soaks wood. It is not going to stay wet in the wood like some Log & Siding Finish. It is going to dry to a hard protective film that resists the harshest weather and black mold stains. |

Hardwood Decks1. Lime Clean

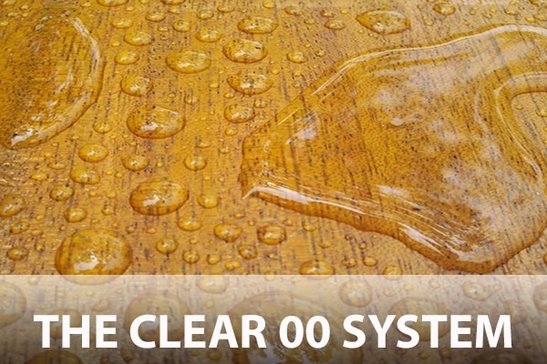

2. 35-50 Grit 3. Mountain XT - Stain Base (diluted 1 quart per gallon with Citrus or Corn Solvent) This section describes a one coat deck stain process for hardwoods. [The Clear 00 System* is a multi-coat system that also can be used on hardwood decks and exterior wood.]

As far as color choices for ipe and exotic woods, we usually go with Almond or similar deeper toned color. The idea is to get the most sun UV blocking without a lot of dark color heat (IR radiation). If you want a lighter brown color then Fawn, Brown Cedar, Brown Cinnamon and Cinnamon Stick are all great colors. Sometimes Mountain XT Stain Base Clear 00 is used on hardwoods. Without any color added the wood can be expected to patina to a natural weathered grey color. With a stain color chosen the wood will resist greying caused by UV / IR Radiation. Prep is important on ipe to get the wood fiber cell to become saturated. The extractives need to be addressed in order for the cell to become open, porous, able to absorb the nourishment. Pressure washing and regular cleaners don't usually do this very well, if at all. We use Lime Clean and the sand with 35 grit on the horizontal areas. This preps the wood well and makes a big difference. If the wood still doesn't soak in Mountain XT full strength, then we add some Pure Citrus Solvent or Corn Solvent. 1 quart per gallon is generally enough to get it to soak in deep and improve durability. Corn Solvent can help speed the dry time on exotic woods which have a natural tendency to slow dry time because of their extractive content. So the usual approach on ipe is: 1. Lime Clean 2. Sand 35-50 grit 3. Mountain XT (diluted one quart per gallon w/ Pure Citrus Solvent) *The Clear 00 System - When we want to keep the clear natural tones of ipe glowing with beautiful wood grain illumination we use The Clear 00 System. But that system must be followed precisely for it to work. No steps can be skipped. The nice thing about it is that it can be maintained with just rolling a clear coat on as needed and the wood doesn't grey; the water rolls away and the sun gets reflected back out to space. The down side to The Clear 00 System is that it is more work at the outset. So, one coat of Rainforest Sealer or Mountain XT - Stain Base is the next best thing to The Clear 00 System. |

Logs | Timbers | SidingDeep, thorough saturation of the wood fiber cell.

All of the true definition and character of the logs will be right up front and visible. This is the best log finish for many reason.

1. It's high solids content saturates wood, resisting splitting. 2. It fortifies the wood with Zinc Oxide and Boric Oxide and locks it in with dense cashew resin. 3. Maintenance coats build upon the previous coat. Rather than stripping and starting over, the wood gets stronger and stronger. 4. Wood Grain Illumination! Mountain XT simply looks gorgeous on wood! Brush or roll it into the logs and it soaks deep into the wood fiber cells providing, natural and long lasting wood protection. XT will dry slowly and deeply into the wood as zinc borate and cashew resin lock out unwanted weather. Our dense cashew resin won't evaporate out like high voc stains that are loaded with solvents. This resin is so thick in the barrel you could jump on it. But that's not how we turn it into the world's best log finish. We can't disclose that secret but we can say the waste from the cashew is actually recycled into resin! To be clear: All the Cashew food still goes to the market! This is very encouraging for sustainability reasons; no petrochemicals, no food supply interruption! |

Wood Fiber CellCaring for each wood cell requires two critical things: Preparation and Saturation.

Lime Clean covers the preparation by removing impediments to deep penetration. Saturation is addressed by meticulous selection of compatible ingredients. Trees, Plants, Minerals and Elements are better than petrochemical based materials. The wood simply seems to like them better. |

INGREDIENT REVIEW:

A beautiful wood finish for exterior wood. The ingredient profile speaks for itself.

Our renewable Cashew based resin is inherently mold resistant. This is the best resin invented since linseed oil. Exterior wood needs a good oil and the cashew resin is absolutely perfect.

Healthy portions of Zinc Oxide and Boric Oxide are locked into the wood fiber cell. This is powerful inorganic protection for wood. (Exempt inert pesticide 25b, Minimal Risk, CFR 180.1121)

Pure Citrus Solvent is made from d-limonene which is also an EPA Exempt Pesticide (CFR 180.1296) used In or On food commodities. Wood simply loves our Pure Citrus Solvent and the wood fiber cell benefits from this ingredient.

Our Corn Solvent is made from Lactic Acid derived from corn. It is an exempt inert pesticide ingredient (40 CFR 180.950(e). Approved for Food, Non Food and Fragrance Uses. Approved for Organic Farming Use (7 CFR 205.605). There are several protective benefits to using this besides the fact that it's strong like MEK without the toxic profile.

Dense Linseed Oils are used which are purified to remove food sources for mold. We rely on the finest techniques to refine our oils. These are made very close to our own factory keeping nearly every ingredient in this product within a days drive from Asheville, NC!

Application ToolsA good brush and roller is still the best way to apply deck stain, siding stain, log finish and finishing Timbers.

For decks we brush the rails. Then we roll and back brush the deck floor. The brush on pole method saves the back. Spraying is fast, it's easy. It's not better. That said, a skilled painter will be able to use the sprayer to apply an even coat that can then be back brushed and worked into the wood. All wood will need to be back brushed after spraying. At the end of the day all jobs benefit from a final back brushing. Wood absorbs finish unevenly. The sap wood is more thirsty than the heart wood. The knots absorb at varying rates. It is good practice to come back at the end of the day and brush any finish still laying on the surface to areas that are more absorbent. This final step cannot be underestimated for it's efficacy. To make back brushing easier we use polls. A brush jammed in the end of a fiberglass pole is a fast and tough tool to work with. With this method an entire 3500 sft Log Home can be back brushed in short order. Seldom will ladders even be needed. |

|

|

| ||||||||||||||||||